(844) 404-4588

24/7 Customer Support

24/7 Customer Support

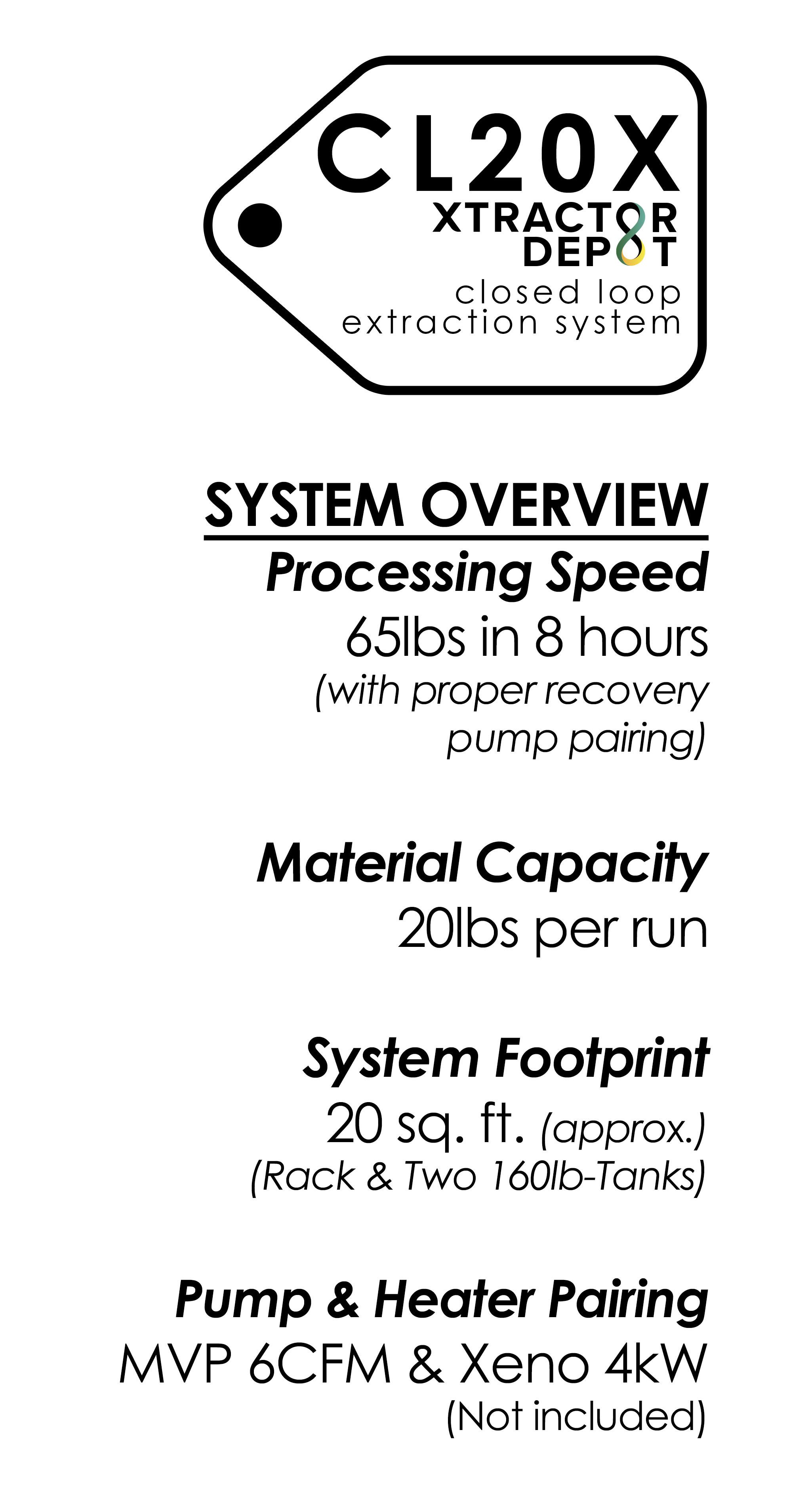

The CL20X hydrocarbon closed loop incorporates the classic components of our standalone Pathfinder system onto a streamlined rackmount unit. This versatile system is designed for efficiency and allows you to perform extraction, remediation, and recovery during each run. It is capable of producing all ‘concentrate’ products found in dispensaries such as Live Resin, Shatter, Wax, and Budder.

Process up to 65lbs of material in an 8 hour day when paired with an MVP 6CFM pump and Xeno 4kW heater. Speak with our sales representative to learn about a full turnkey option that meets your needs. TRAINING INCLUDED when you purchase a complete turnkey system!

Features:

20lb (packed) total material holding capacity.

ASME Modular HX for use with dry ice or a chiller

I.R.C. for use with all remediation powder types

Filter dryer aids removal of moisture during solvent recovery (molecular sieve required)

Powder-coated rack for an additional layer of protection against chipping and corrosion

Locking 360 Degrees caster wheels

Superlok ball valves

Sprayball Caps

Pressure release valves (PRV)

Fused sight glasses

Specifications

Material Columns: 6″ x 48″ non-jacket

Collection Vessel & Solvent Tank: ASME 160lb (water weight) single-jacket

Connections: 1/2″ Compression Fittings, 1/2″ FJIC Hoses

Pressure Release Valves: Rated 150-250PSI (depending on configuration)

Pressure Gauges: -30 inHg to 300 PSIG

Screen Gasket: Viton 4″ 5u-20, Viton 4″ 150-20, 6″ Viton 50 Mesh

Sintered Disc: 5um

Sight Glasses: 3″ Fused Tri-Clamp

Footprint : 4.3′ L x 3.1′ (13.6 square feet approx.)

Dimensions: 4.3″ L x 38″ D x 84″ H (approx.)

Accessories Included:

10 x 25um material socks 6″ x 48″

1 x Packing hopper

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.